spherene metamaterial

Discover spherene, a new class of minimal surfaces that adapt seamlessly to any shape. They're freely configurable, resilient, and resource-efficient.

Events

News

2023

SEPT 22-23

OCT 18-20

NOV 07-10

2024

MAY 07-08

MAY 14-17

SEPT 4

Control the Complex

Introducing spherene -- the revolutionary technology behind next-generation manufacturing solutions.

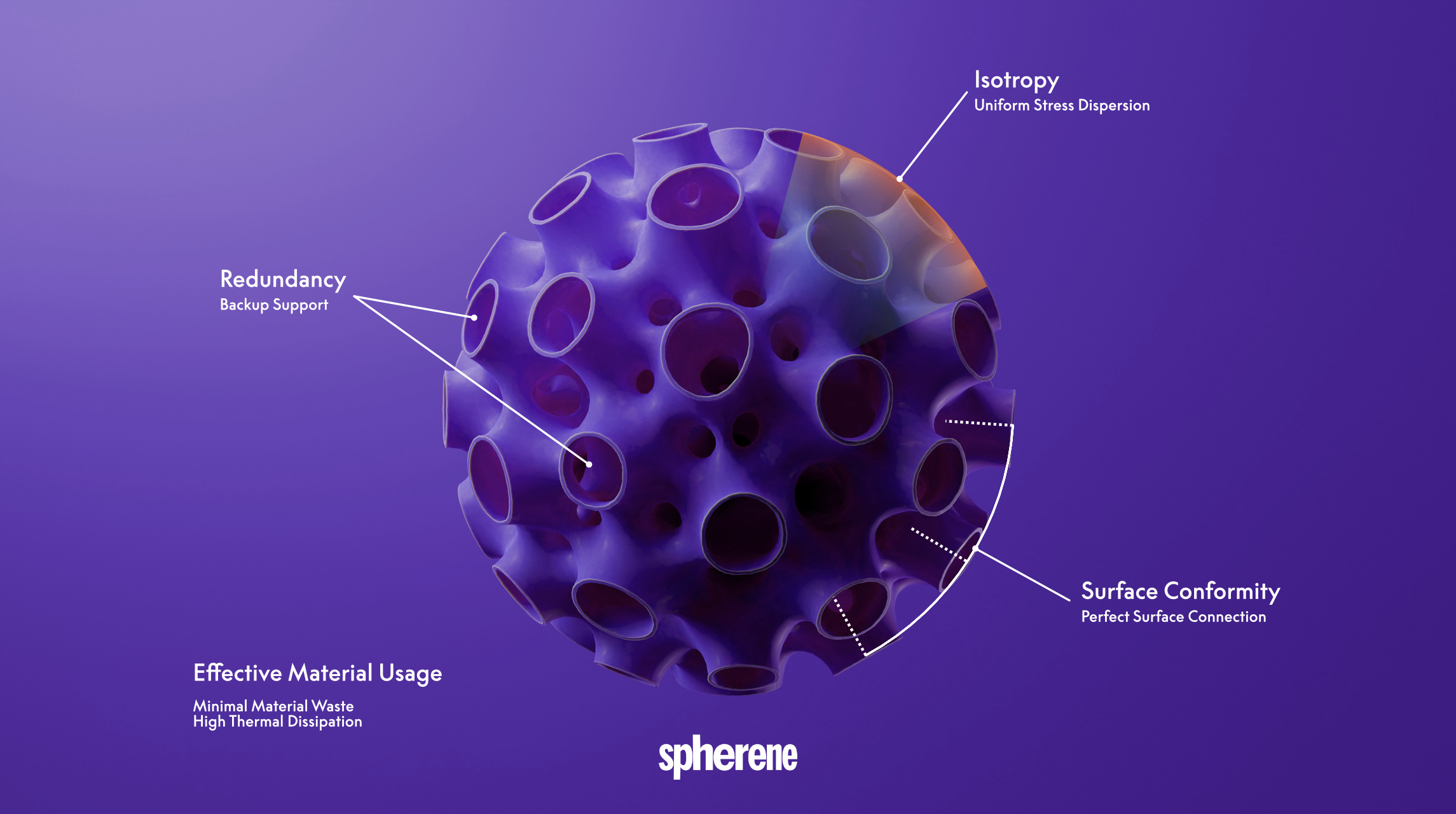

Spherene is a groundbreaking new class of isotropic, aperiodic minimal surfaces known for their adaptive density and exceptional surface conformity. These unique structures enable the design of versatile components that maximize strength while minimizing material use. Spherene is a real metamaterial.

Acting like solid materials, spherene effectively distributes stress and offer adjustable elasticity and high stiffness, making it ideal for diverse applications from footwear and orthopedic designs to aerospace engineering.

In the realm of additive manufacturing, spherene stand sout for its efficient material usage. It facilitate easy depowdering and high thermal dissipation, which translates into considerable cost savings and reduced environmental impact.

Key Features at a Glance

- Efficient, isotropic stress distribution for superior performance.

- Cutting-edge metamaterial technology.

- Parametric control for tailored solutions (Density, Wall Thickness, Cavities, Surface Bias, Modifier geometries).

- Minimal need for support structures in manufacturing.

- Versatile constructions: open-pored for breathability and closed for solidity.

- Simplified post-production with easy depowdering.

Photos and 3D Print: Rapidia

Femur, qualitative interpretation using spherene. Printed on a Rapidia Conflux 1 using 316L stainless steel paste

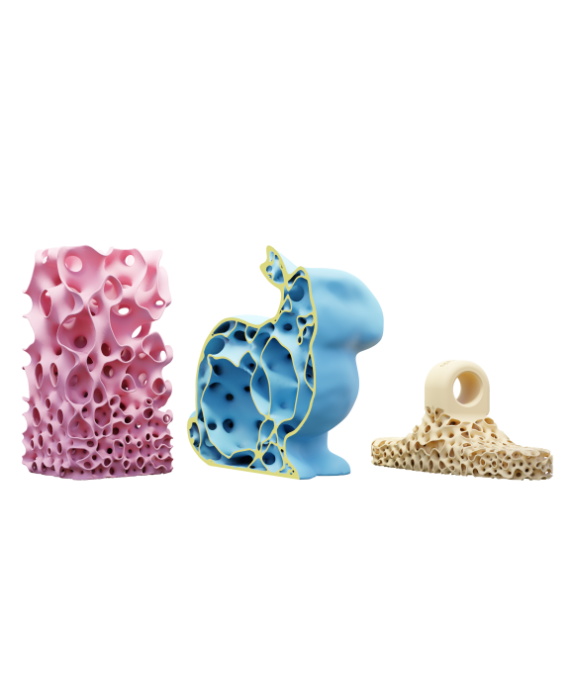

Autonomous design using spherene lets you control structural features like density, porosity, thickness, heterogeneity, and organic integration with interfaces.

“With Rapidia's easy to use interface and materials selection, I was able to take spherene's ADMS femur from print bed to sintering furnace with little modification.

The unique open geometry of spherene's design allowed for me to selectively use Rapidia's evaporative support geometry where I needed it, and leave other sections self-supported.”

Connor Lagroix, Rapidia

Made for Manufacturing

Spherene minimizes the need for support structures in 3D printing, achieves low thermal stresses, and allows open channels for optimal material utilization that retains solid-like properties, exceptional rigidity, and an unparalleled ability to adapt to any surface while distributing stresses effectively. Enhance your current manufacturing techniques by integrating spherene.

Printable Samples

Print spherene samples suitable for all 3D printing techniques (FDM/SLA/SLS/SLM), compatible with a variety of materials such as filament, resin, metal, and ceramics.

Eliminate the need for extra support structures. Experience the advantages of spherene firsthand.

"spherene introduces a completely new way of thinking about how components can be designed and laid out, which has been lacking until now."

Matthias Blaser, Zühlke Engineering

"...clearly addressing one of the cross-cutting themes of the ESA technology strategy, but in a novel way."

Moritz Fontaine, European Space Agency